PRODUCTS

FEATURE

|

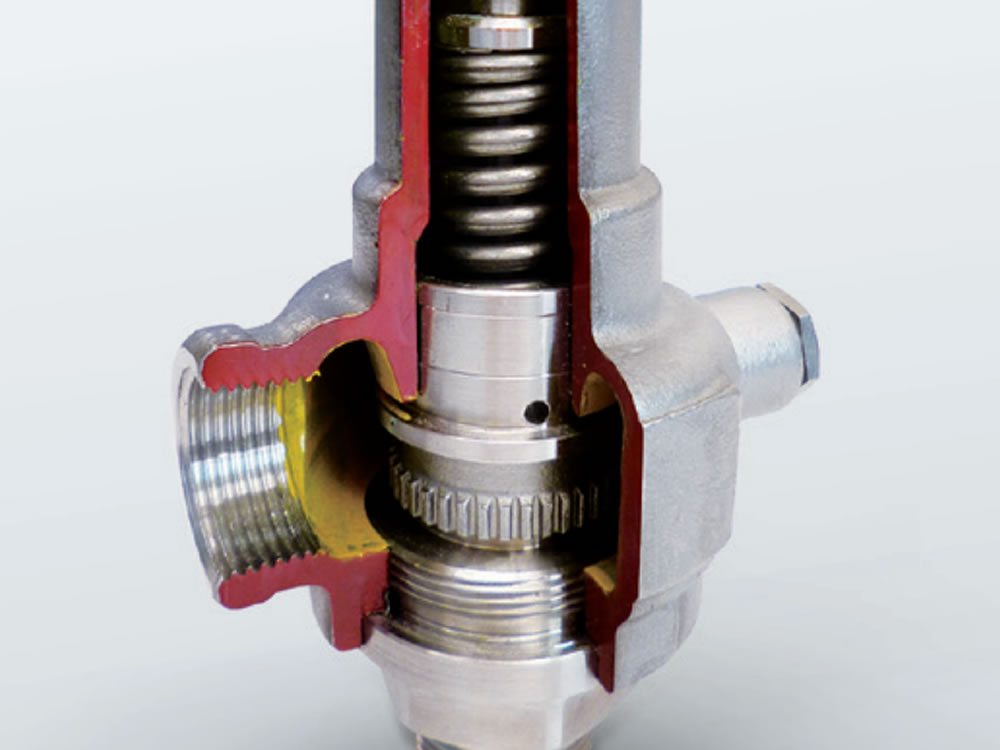

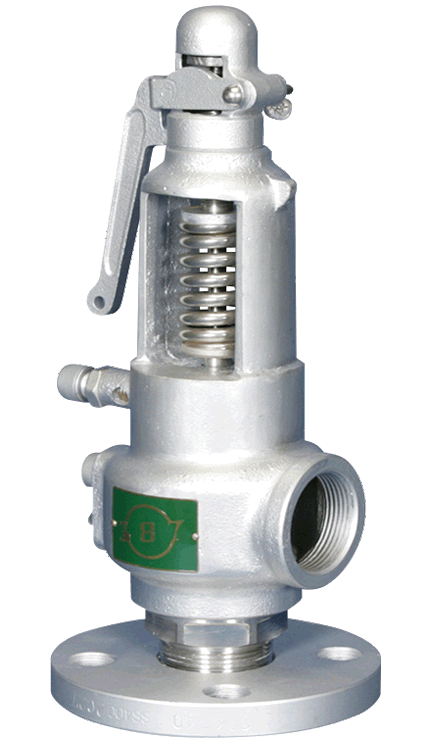

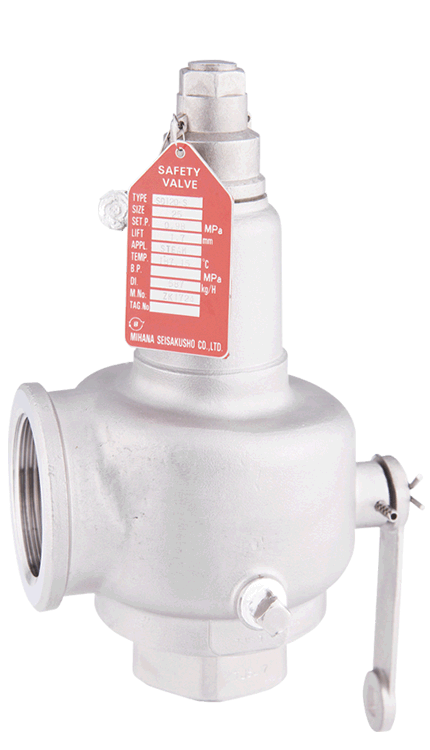

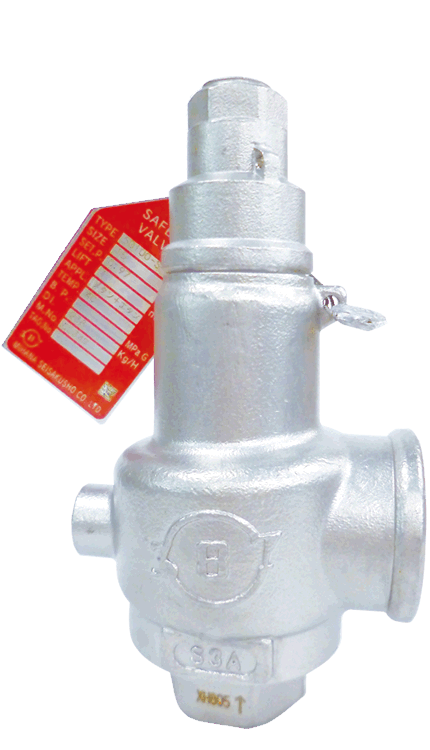

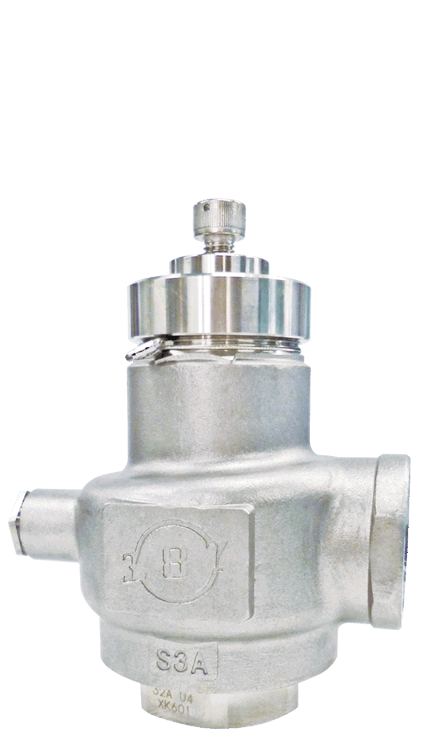

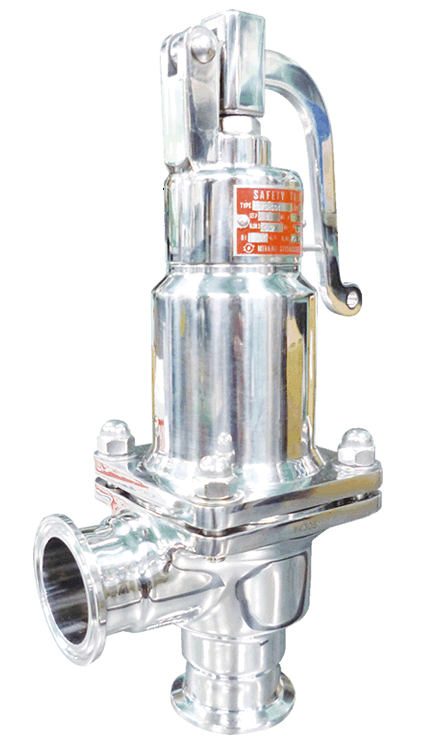

NO START TO DISCHARGE Our Uniquely Engineered Technology completely avoids the discharge. So, there is No Start to Discharge due to our technology. Mihana has achieved the world’s first “simultaneous start to discharge and popping” using a special mechanism developed with our proprietary technology. |

|

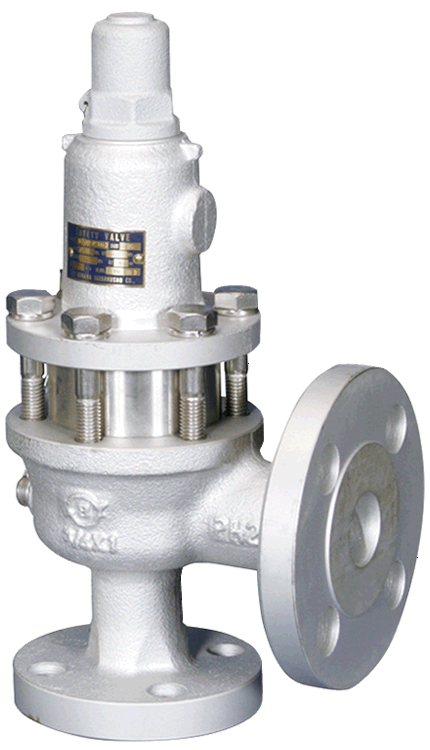

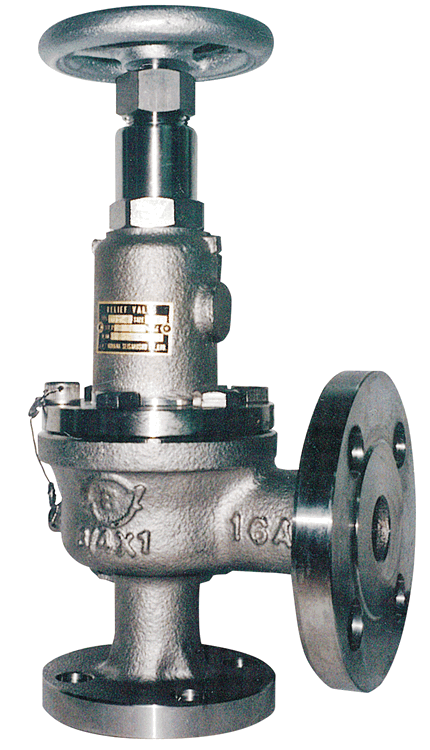

HIGH RIGIDITY When Safety Valves are popping the reaction is received at the weakest part, Inlet Flange Neck. Our Bolted Structured Safety Valves are engineered without such neck and feature a Rigid Design, so there is no risk of damage due to the reaction force and they can handle high pressure application.

|

|

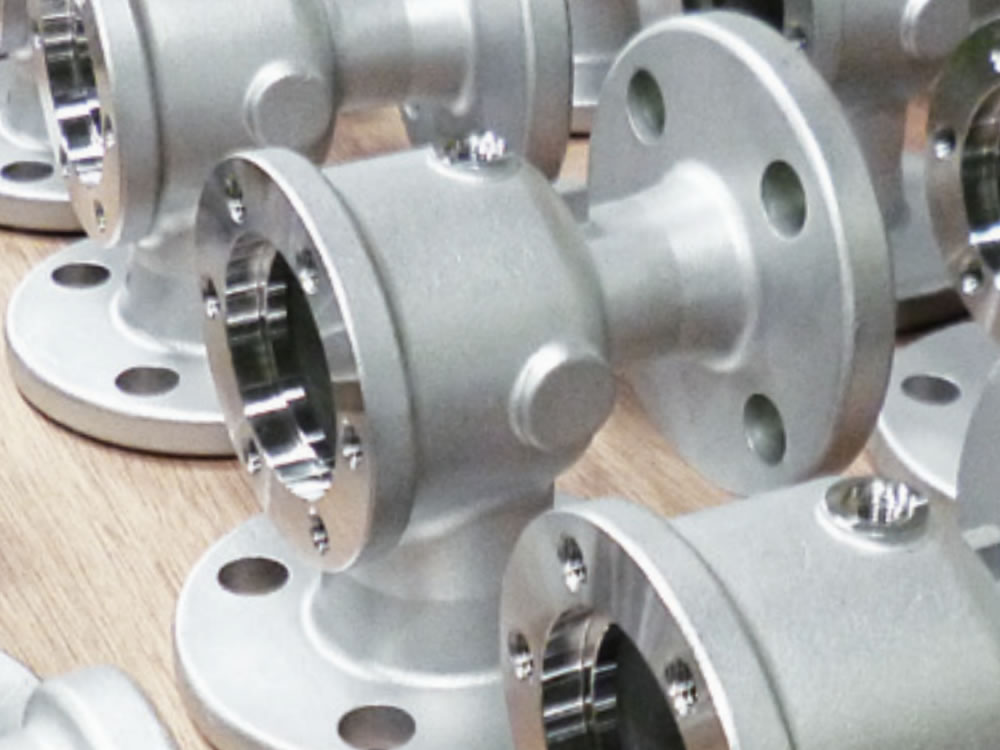

THOROUGH QUALITY CONTROL We conduct thorough material analysis to ensure our customers can use our products with confidence, especially since we source many parts from overseas. By preventing issues related to incorrect materials, we aim to deliver high-quality performance, enhance customer satisfaction and achieve cost saving through improved production uptime. |

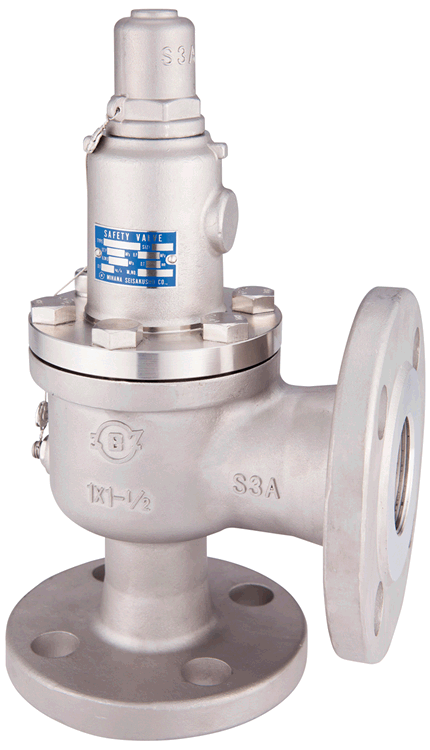

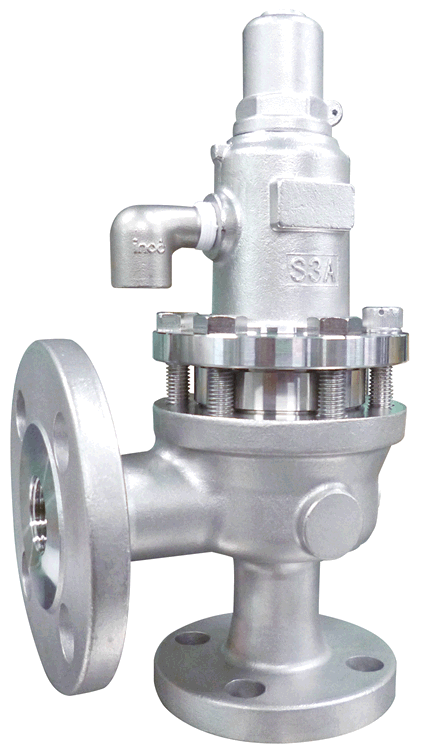

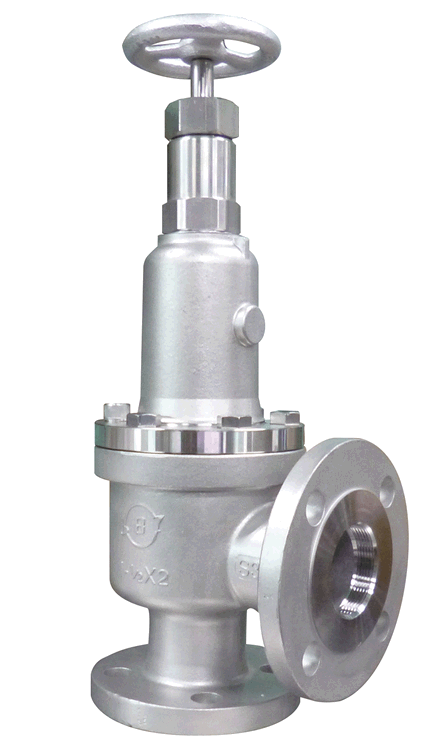

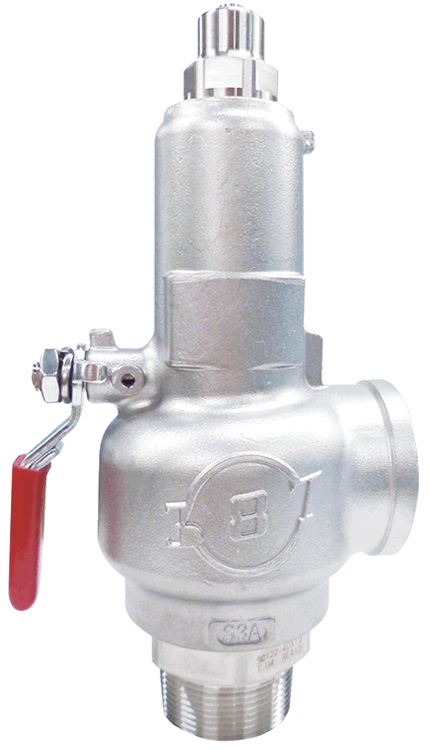

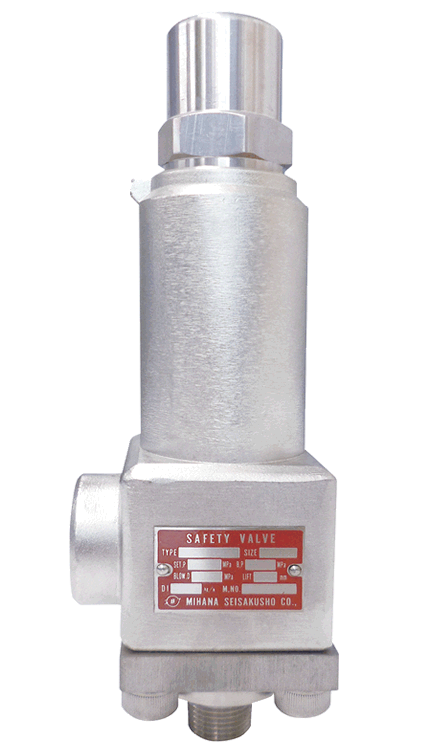

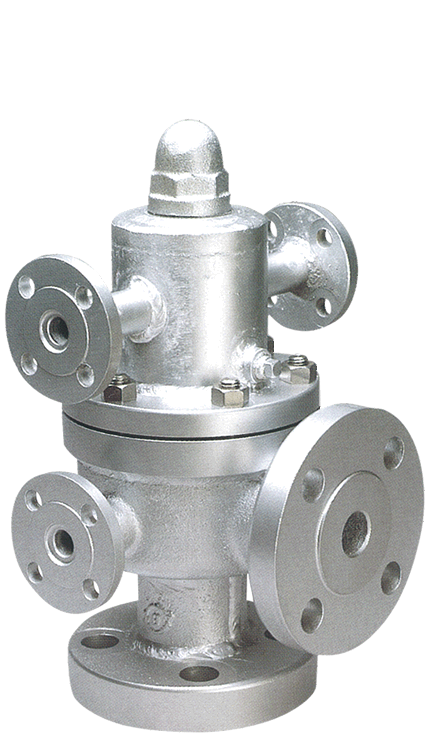

FULL BORE SAFETY VALVE

Safety valve capable of obtaining a lift where the seat flow area becomes sufficiently larger than the area of the throat.

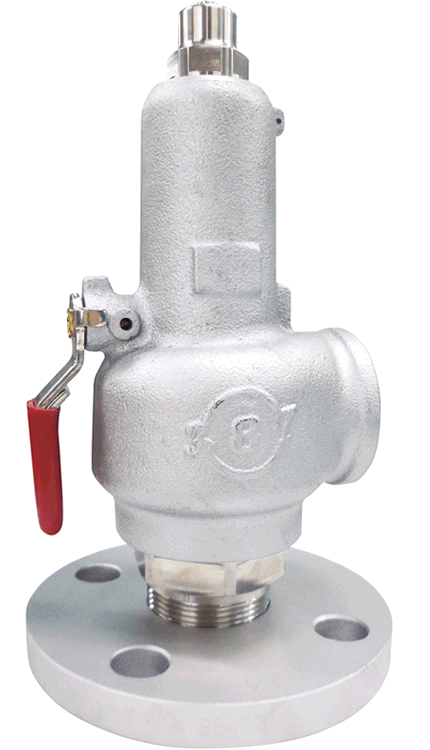

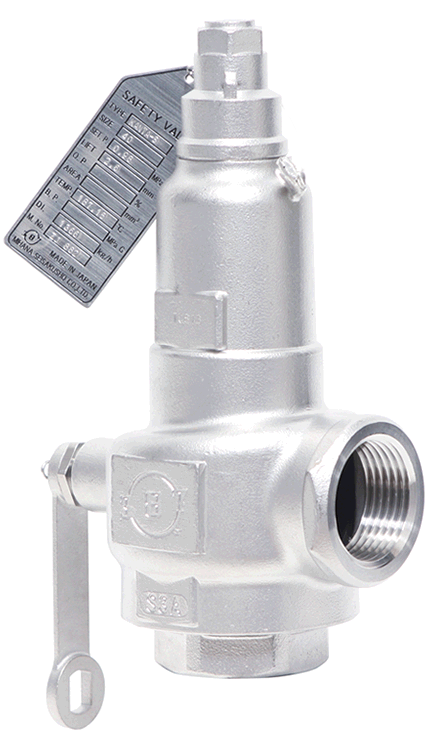

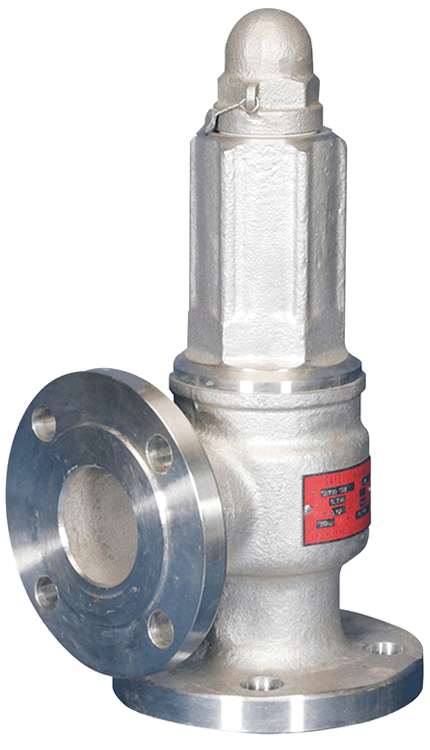

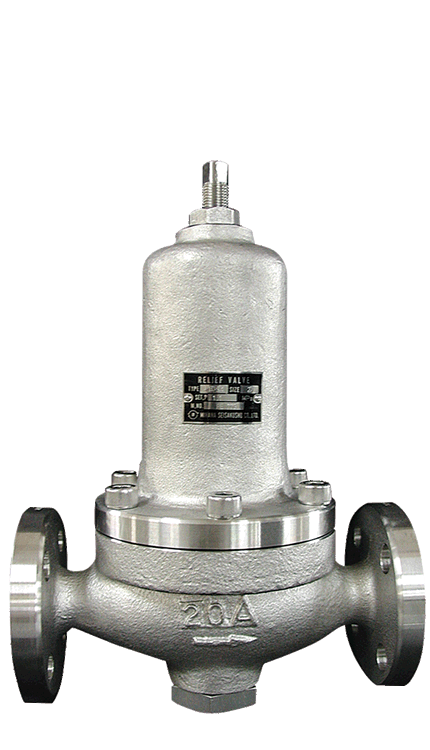

CURTAIN AREA RESTRICTED SAFETY VALVE

Safety valve of which the lift is 1/40 or over to and excluding 1/4 the seat diameter, and of which the seat flow area (curtain area) is the smallest of all flow areas with the valve disc opened.

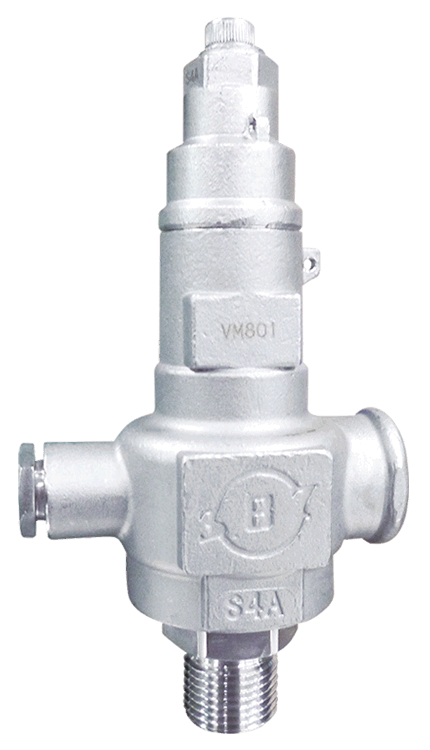

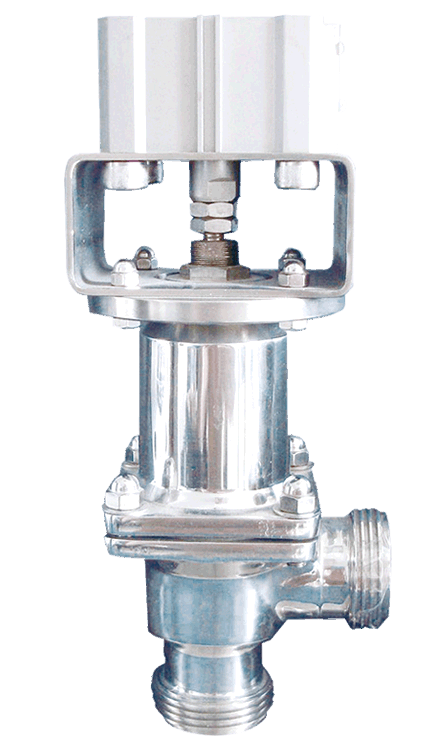

OTHERS

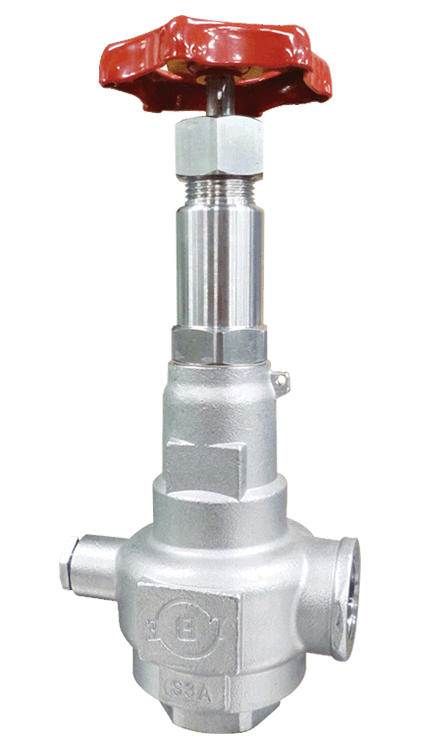

ACCESSORIES

For more information

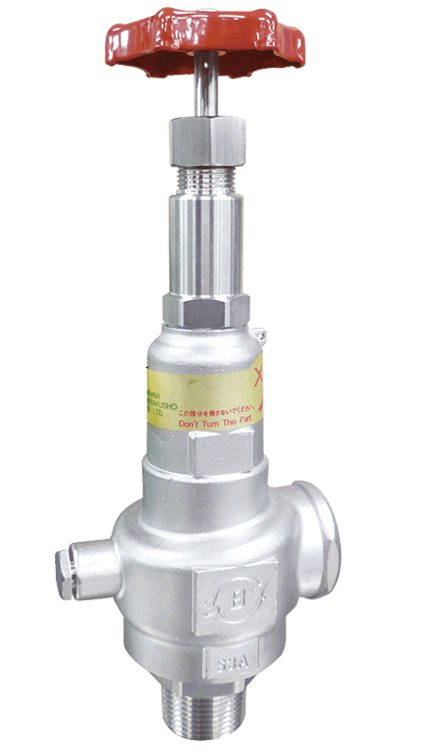

SA100

SA100 SA110

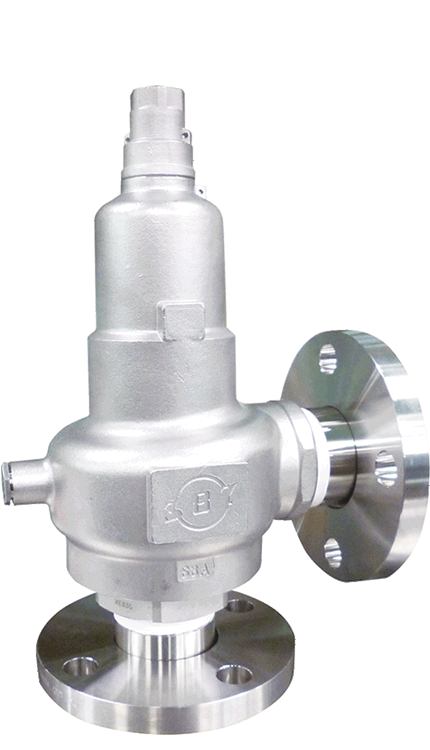

SA110 SA500

SA500 SA200

SA200 RA100

RA100 SG122

SG122 SG922

SG922 SC121

SC121 SC122

SC122 KANTA/KNATAE

KANTA/KNATAE KANTAB

KANTAB HKANTAE

HKANTAE HKANTAB

HKANTAB KANTAK

KANTAK HKANTAK

HKANTAK SD10X

SD10X SD103

SD103 SB101

SB101 SB100

SB100 RB101

RB101 M8W

M8W SC120

SC120 SD120

SD120 SD100

SD100 S3FSC

S3FSC SKANTAE

SKANTAE M8FBJ

M8FBJ RFSBD

RFSBD SVS

SVS SVSC

SVSC SVSSA

SVSSA